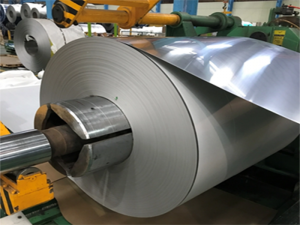

201 Stainless Steel Coil

Description

Specifications:

1.Standard: ASTM A240, JIS G4304, EN10088

2.Grade: 200series&300series&400series

3.Thickness: 0.03mm - 6.0mm

4.Width: 8mm-600mm

5.Length: as customers' request

6.Surface: 2D,2B, BA, Mirror finished, N04, Hair Line, Matt finish, 6K, 8K

7.Technology: cold drawn/cold rolled/hot rolled

Corrosion resistance

The general level of corrosion resistance of Type 201 is similar to Type 301. Type 201 should perform adequately as a replacement for

Type 301, in most mild environments. The scaling resistance of Type 201 is less than that of Type 301. Type 201 resists destructive scaling up to about 1500 °F (816 °C), about 50 °F (28 °C) less than Type 301.

Fabrication

Type 201 Stainless Steel can be fabricated by bench forming, roll forming and brake bending in much the same manner as Type

301. However, because of its higher strength, it may exhibit greater springback. This material can be drawn similarly to Type 301 in most

drawing operations if more power is used and the hold-down pressure is increased.

Weldability

The austenitic class of stainless steels is generally considered to be weldable by the common fusion and resistance techniques. Special

consideration is required to avoid weld “hot cracking” by assuring formation of ferrite in the weld deposit. As with other chrome-nickel

austenitic stainless steel grades where carbon is not restricted to 0.03% or below, the weld heat affected zone may be sensitized

and subject to intergranular corrosion in some environments. This particular alloy is generally considered to have poorer weldability to

the most common alloy of this stainless class, Type 304L Stainless Steel. When a weld filler is needed, AWS E/ER 308 is most often

specified. Type 201 Stainless Steel is well known in reference literature and more information can be obtained in this way.

Heat treatment

Type 201 is not hardenable by heat treatment. Annealing: Anneal at 1850 – 1950 °F (1010 – 1066 °C), then water quench or rapidly air cool. The annealing temperature should be kept as low as possible, consistent with the desired properties, because Type 201 tends to scale more than Type 301

|

Stainless Steel grade |

|||||||

|

Grade |

Chemical composition |

||||||

|

C≤ |

Si≤ |

Mn≤ |

P≤ |

S≤ |

Ni |

Cr |

|

|

201 |

0.15 |

1.00 |

5.5-7.5 |

0.5 |

0.03 |

3.50-5.50 |

16.00-18.00 |

|

202 |

0.15 |

1.00 |

7.5-10.0 |

0.5 |

0.03 |

4.00-6.00 |

17.00-19.00 |

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.03 |

8.00-11.00 |

18.00-20.00 |

|

304L |

0.03 |

1.00 |

2.00 |

0.045 |

0.03 |

8.00-12.00 |

18.00-20.00 |

|

309 |

0.2 |

1.00 |

2.00 |

0.04 |

0.03 |

12.00-15.00 |

22.00-24.00 |

|

309S |

0.08 |

1.00 |

2.00 |

0.045 |

0.03 |

12.00-15.00 |

22.00-24.00 |

|

310 |

0.25 |

1.50 |

2.00 |

0.04 |

0.03 |

19.00-22.00 |

24.00-26.00 |

|

310S |

0.08 |

1.00 |

2.00 |

0.045 |

0.03 |

19.00-22.00 |

24.00-26.00 |

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.03 |

10.00-14.00 |

16.00-18.00 |

|

316L |

0.03 |

1.00 |

2.00 |

0.045 |

0.03 |

10.00-14.00 |

16.00-18.00 |

|

316Ti |

0.08 |

1.00 |

2.00 |

0.045 |

0.03 |

10.00-14.00 |

16.00-18.00 |

|

2205 |

0.03 |

1.00 |

2.00 |

0.03 |

0.02 |

4.50-6.50 |

22.00-23.00 |

|

410 |

0.15 |

1.00 |

1.00 |

0.04 |

0.03 |

0.6 |

11.50-13.50 |

|

430 |

0.12 |

0.12 |

1.00 |

0.04 |

0.03 |

0.6 |

16.00-18.00 |