316L Stainless Steel Bar

Description

Production procedure:

Raw elements (C, Fe, Ni, Mn, Cr and Cu), smelted into ingots by AOD finery, hot rolled into black surface, pickling into acid liquid, polished by automatically machine and cutting into pieces

Standards:

ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311 and JIS G 4318

Dimensions:

Hot-rolled: Ø5.5 to 110mm

Cold-drawn: Ø2 to 50mm

forged: Ø110 to 500mm

Normal length: 1000 to 6000mm

Tolerance: h9&h11

Features:

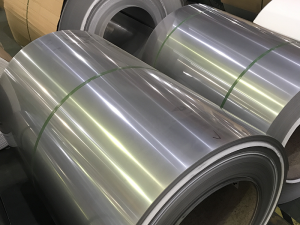

Nice appearance of cold-rolled product gloss

Nice high temperature strength

Nice work-hardening (after processing weakly magnetic)

Non-magnetic state solution

Suitable for architectural, construction and other applications

Applications:

Construction field, ships building industry

Decoration materials and outdoor publicity billboard

Bus inside and outside packaging and building and springs

Handrails, electroplating and electrolyzing pendants and foods

Corrosion- and abrasion-free to meet specific requirements of various machinery and hardware fields

Grades of stainless steel bar

| Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | ||

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 |

Basic information

316 and 316/L (UNS S31600 & S31603) are molybdenum-bearing austenitic stainless steels. The 316/316L stainless steel bar, rod and wire alloy also offer higher creep, stress to rupture and tensile strength at elevated temperatures, in addition to excellent corrosion resistance and strength properties. 316/L refers to the lower carbon content to allow for greater corrosion protection when welding.

Austenitic steels have austenite as their primary phase (face centered cubic crystal). These are alloys containing chromium and nickel (sometimes manganese and nitrogen), structured around the Type 302 composition of iron, 18% chromium, and 8% nickel. Austenitic steels are not hardenable by heat treatment. The most familiar stainless steel is probably Type 304, sometimes called T304 or simply 304. Type 304 surgical stainless steel is austenitic steel containing 18-20% chromium and 8-10% nickel.