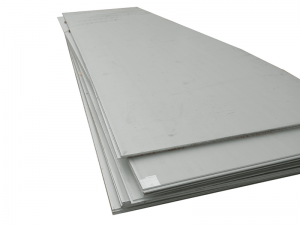

321 Stainless Steel Strip

Stainless Steel Sheet Plate Grade Baogu Supply

| Type | Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.431 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.455 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| xm-19 | Nitronic50 | ≤0.06 | 20.50-23.50 | 11.50-13.50 | 4.0-6.0 | ≤0.045 | ≤0.030 | 1.50-3.00 | ≤1.00 | - | 0.2-0.4 | Nb:0.10-0.30 V:0.10-0.30 | |

| 904L | N08904 | ≤0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.045 | ≤0.035 | ≤1.00 | 0.1 | Cu:1.0-2.0 | |||

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| * | S32760 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.00 | ≤0.030 | ≤0.010 | 3.0-4.0 | ≤1.00 | 0.5-1.00 | 0.2-0.3 | ||

| 2304 | S32304 | ≤0.03 | 21.5-24.5 | 3.0-5.5 | ≤2.50 | ≤0.040 | ≤0.030 | 0.05-0.6 | ≤1.00 | 0.05-0.6 | 0.05-0.2 | ||

| 329 | 1.446 | ≤0.08 | 23.00-28.00 | 2.00-5.00 | ≤1.00 | ≤0.040 | ≤0.030 | 1.00-2.00 | ≤0.75 | - | - | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| 446 | S44600 | ≤0.20 | 23.00-27.00 | 0.75 | ≤1.5 | ≤0.040 | ≤0.030 | 1.50-2.50 | ≤1.00 | - | ≤0.25 | - | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 416 | Y1Cr13 | ≤0.15 | 12.00-14.00 | 3) | ≤1.25 | ≤0.060 | ≥0.15 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 431 | 1Cr17Ni2 | ≤0.20 | 15.00-17.00 | 1.50-2.50 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤0.80 | - | - | - | |

| 440C | 11Cr17 | 0.95-1.20 | 16.00-18.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | 0.75 | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Description

321 stainless steel strip is a type of austenitic stainless steel with low carbon content and good corrosion resistance to many corrosive environments. 321 offers excellent weldability, good machinability and outstanding fabrication properties.

321 stainless steel strip is commonly used in the chemical industry, pulp and paper industry, marine and offshore engineering industries as well as in the food and beverage industries.

321 stainless steel strip also has a high level of resistance to chloride stress corrosion cracking and pitting. It is also resistant to hydrochloric acid at elevated temperatures up to 250°C (480°F).

Features

Good Corrosion Resistance: 321 stainless steel strip has better corrosion resistance than 304 and 316 types of stainless steels, which makes it ideal for use in corrosive environments.

Excellent Weldability: 321 stainless steel strip can be welded by all methods including arc welding ( TIG / GTAW ), electron beam welding ( EBW / EFW ), submerged arc welding ( SAW ) and laser beam welding ( LBIW ).

High Strength: The strength levels of 321 stainless steel strip are up to 50% higher than those of 304 types of stainless steels and up to 80% higher than those of 316 types of stainless steels due to their increased carbon content and austenite grain size.